- Email: engapp.waluj@yahoo.com

- E-36, MIDC, Waluj, Aurangabad

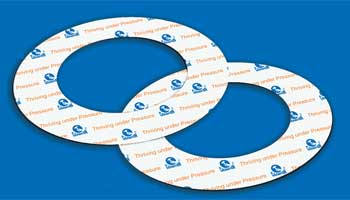

Champion UFG (e PTFE Ultimate Flange Gasket) material is capable of a wide service range in applications found throughout process industries. The UFG multilayer manufacturing method provides reliable sealability due to the low stress and exceptional dimension stability characteristics the material possesses. This form of gasketing material is processed by expanding 100% pure polytetrafluoroethylene (PTFE) into a highly fibrillated, bi-directional, soft, compressible gasket for longer life and trouble free sealing. Its form-in-place versatility is perfect for flange surfaces that are worn, warped or scored.

The distinct compressibility of the UFG gasket enables it to effectively fill flange imperfections for a tight, leak-free seal. Unlike conventional PTFE materials which are prone to cold flow, UFG has good creep resistance and bolt torque retention properties. The Champion UFG material has excellent chemical resistance with a pH range of 0 to 14, making it suitable for most medium. The temperature service parameters range from -450°F (-268°C) to 500°F maxiumum/600°F spike (260°C/315°C) and pressure ranges from full vacuum to 3,000 psi (206 bar).

These exceptional values are achieved without the need of filler materials like silica, barium sulfate or hollow glass spheres. The Champion UFG material is ideal for both high load metal flanged applications and low load applications such as glass-lined steel, glass and FRP (fiberglass reinforced plastic) piping and vessels.

It does not support bacterial growth or cause product contamination and is FDA 21 CFR 177.1550 certified.

| Description | Industrial grade |

| Length Tensile Strength | 17.0MPa |

| Cross Tensile Strength | 27.0MPa |

| Compressive Strength | 14.7MPa & Max : 20.0MPa |

| Temperature | upto 260。C |

| Density | 0.80-0.95 g/cm3 |